NEW ARRIVALS

-

4GB Micro SD Card

$12.00 Add to cart -

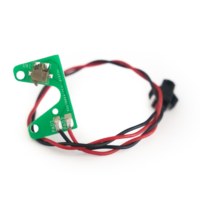

C Endstop Harness

$9.00 Add to cart -

D Endstop Harness

$14.00 Add to cart -

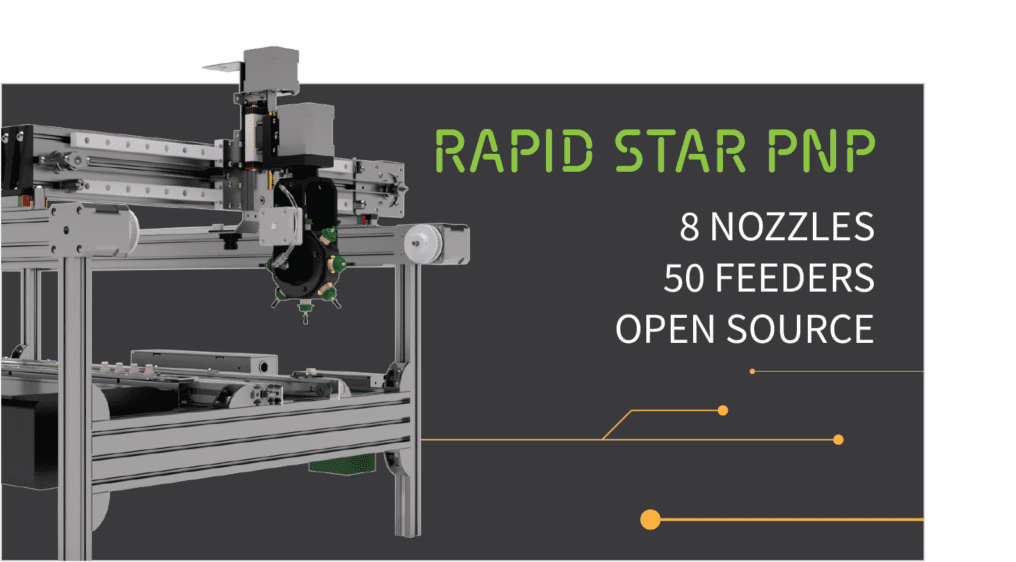

Rapid Star Head

$239.00 Add to cart -

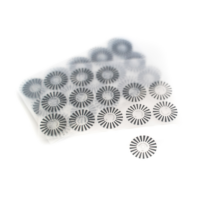

42 Pulse Encoder Disc

$0.99 Add to cart -

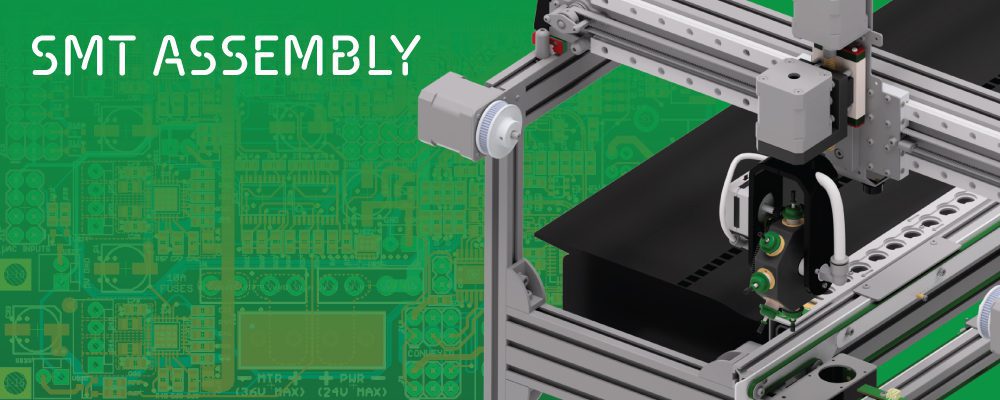

SMT Conveyor Belt

$14.00 Add to cart -

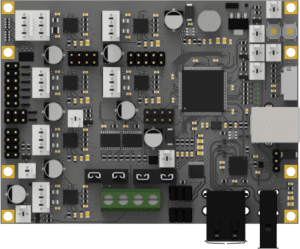

Conveyor Board

$9.00 Add to cart -

Vacuum Sensor Board

$19.00 Add to cart -

Plastic Tube Fitting for Air & Water

$0.75 Add to cart -

Y Motor Harness

$9.00 Add to cart -

Power Supply Wires

$12.00 Add to cart -

Signal Harness

$19.00 Add to cart

WHY US?

FAST SHIPPING

Stocked and shipped from our USA warehouse same or next day with tracking and insurance.

QUALITY GUARANTEED

We work directly with our suppliers for strict quality control and inspect every part that we sell.

COMMUNITY

We don’t just design products, we also open source them and have an online community of members.

CUTTING EDGE

We design and manufacture our own products to improve your experience and innovate on new ideas.