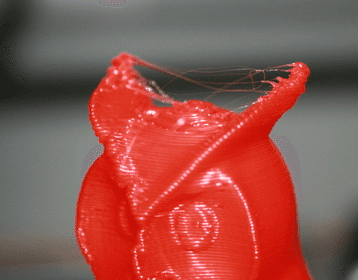

Stringing is often the result of poor retraction. Retraction is when your printer’s nozzle “sucks” the plastic back in when it finishes printing a segment of your print and travels to a new point to start printing again.

Stringing is often the result of poor retraction. Retraction is when your printer’s nozzle “sucks” the plastic back in when it finishes printing a segment of your print and travels to a new point to start printing again.

You should first make sure that retraction is enabled in Cura. This setting is found on the “Basic” tab in the form of a checkbox when you are in the full settings mode (Expert -> Switch to full settings…). Make sure this box is checked.

There are several settings you can try playing around with to lessen or eliminate the effect of stringing:

- By default the Delta Go settings in Cura have a 0.20mm z-hop under Expert Settings tab. This may create a bit of stringing. You can turn this off by changing the value to 0. Note that you’ll have to take extra precaution that your layers don’t warp up, otherwise the hotend may hit it. With Z-hop enabled, it helps to make sure your hotend doesn’t hit the layers as it travels.

- Experiment with different temperatures when printing. Just make sure that you don’t lower it so much that you develop under-extrusion issues because the plastic will be too solid to push out the nozzle.

- See if increasing the travel speed helps. This will lower the time the plastic has to ooze out the nozzle in between segments of your print.

- You can also increase retraction, although our recommended print settings are already tested to work well. Increasing retraction may increase your print time very slightly because the printer has to wait for the extruder motor to finish retracting the filament. Do NOT increase your retraction over 4.10mm as you are likely to jam the hotend on your Delta Go 3D printer.

On some prints that have a lot of gaps in between features you may experience slight stringing. If the stringing is very thin like a spider’s web, it is usually advisable to just remove it post-print by hand instead of fiddling with settings that you then might need to revert back to for other more common prints.

Also, make sure that the extruder motor is not overheating. This is common when you’re printing many features on a single print that have very small surface area, thus forcing the extruder to constantly push and pull the filament every few seconds instead of pushing the plastic for the most part.