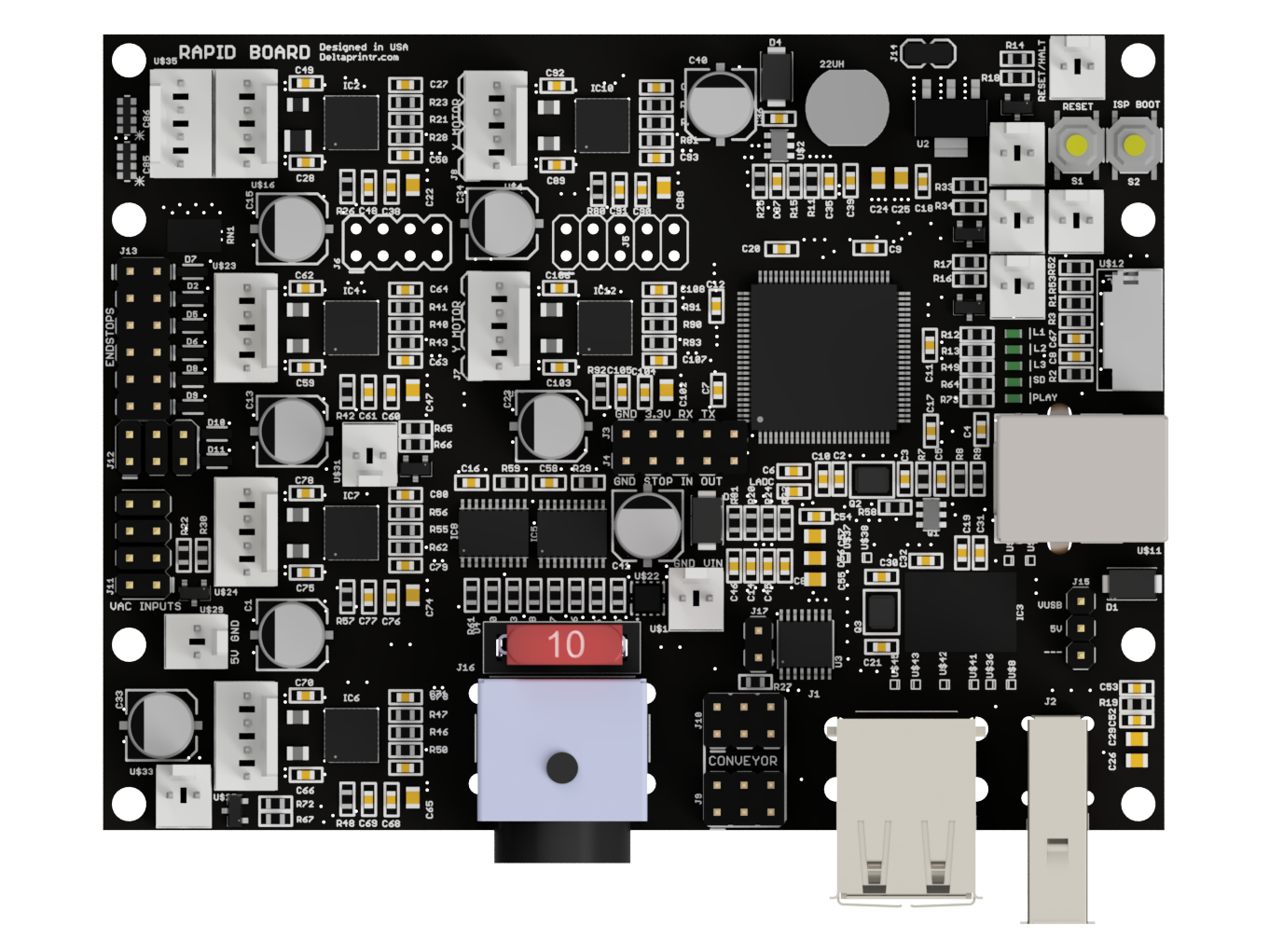

Description

Setup instructions can be found here.

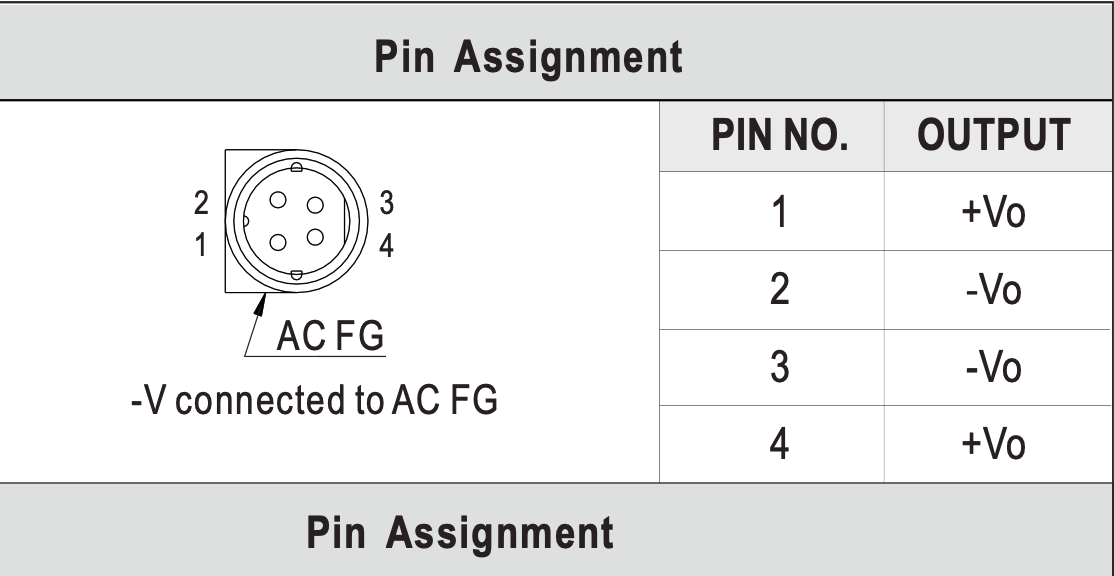

NOTE: The latest board design uses a DIN power supply plug. You need to purchase a power supply brick that has the same connections as this model. Using a power supply brick with same connector model but wrong pin configuration can fry the board!

Features

- Runs on Smoothieware

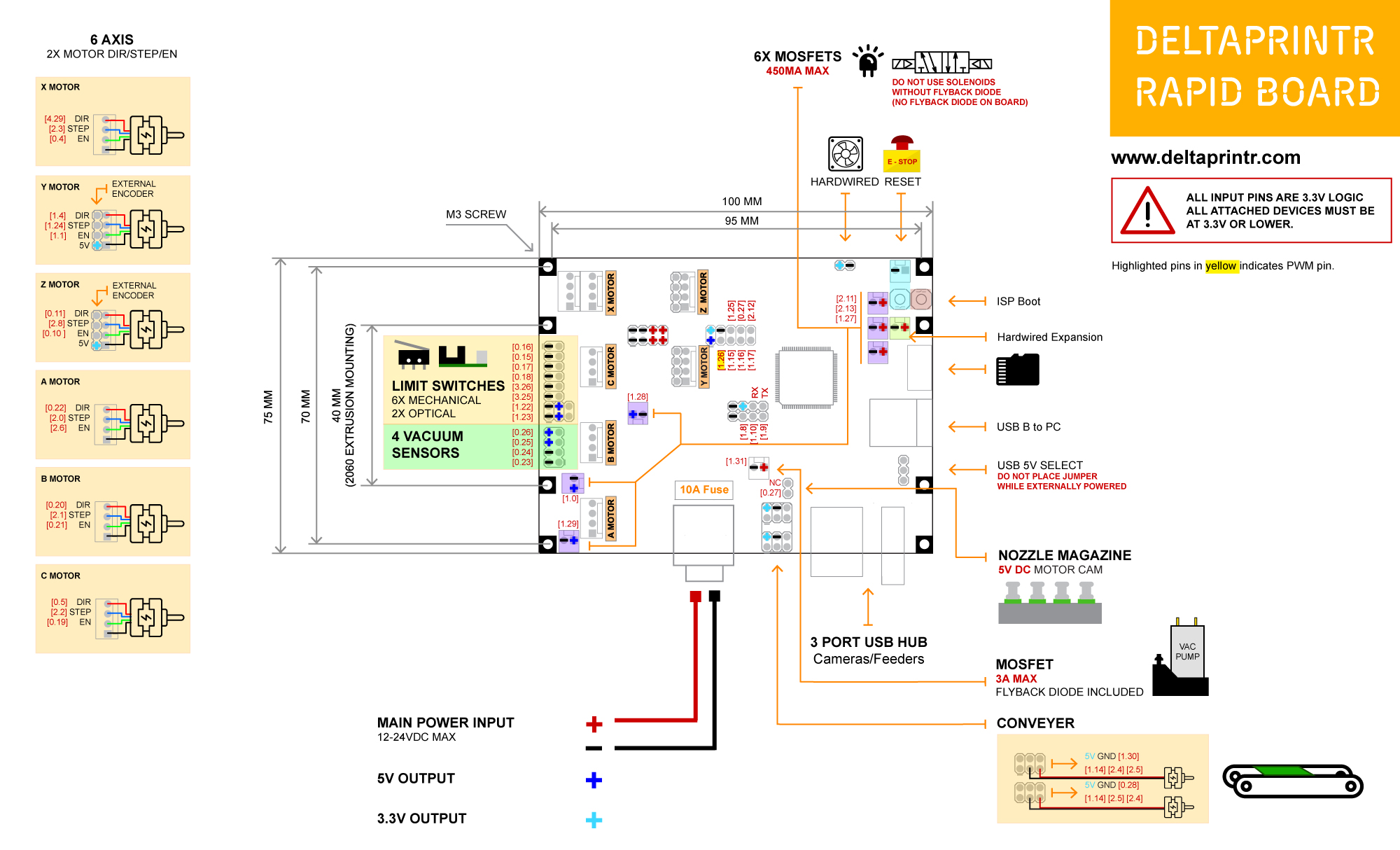

Available in two versions:

A) Regular version – All axis drivers are populated with TMC2208

B) Encoder version – Only nozzle rotation and Z axis for nozzles are TMC2208. X and Y axis drivers are un-populated and instead have DIR/STEP/EN pinout to connect an external encoder driver (sold separately). - Can drive up to 6 stepper motors.

- Separate power rails – Max 36V for motors and 24V for board with fuses (included).

- 4 port USB Hub – reduce cable clutter by connecting only one USB cable to your machine. Both cameras, feeder and smoothie board itself connect via the hub.

- Four vacuum sensor connections.

- Seven mosfets.

- 3x 450mA hardwired to power input voltage (lights, solenoids, etc.)

- 3x 450mA 5v (solenoids, actuators, servos, etc.)

- 1x 3A hardwired to power input voltage – vacuum pump with flyback diode for protection included.

- Micro SD Card slot – Configuration is easier using a text based config file loaded on the SD card, no need to upload firmware every time you make a change. Just edit the config file from your PC then reboot the board with the new config and you’re done. (Micro SD card not included)

- Conveyor setup:

A) IN, OUT, STOP signal connections for another PNP or reflow oven.

B) DRV8833 on board for conveyor motor control, capable of driving dual motors on both sides of conveyor.

C) Board-In & Board-Out connections to know when your board has moved into the PNP and left it. - Two camera connections via USB A.

- Eight end stops! 6x mechanical and 2x optical

- Emergency Halt/Reset connection.

- Nine expansion pins, in addition to GND, 5V and POWER VIN.

Required tools/material

Power Supply

External encoders if choosing encoder version

Micro SD card (sold separately here)

What’s included

1x Rapid Star Board

2x 10A Fuses